1000kg+ Heavy Tube Processing Can't Do Without--- HSG Four-chuck Heavy-duty Tube Laser Cutting Machines

Post date: 2022-10-24 10:44:54

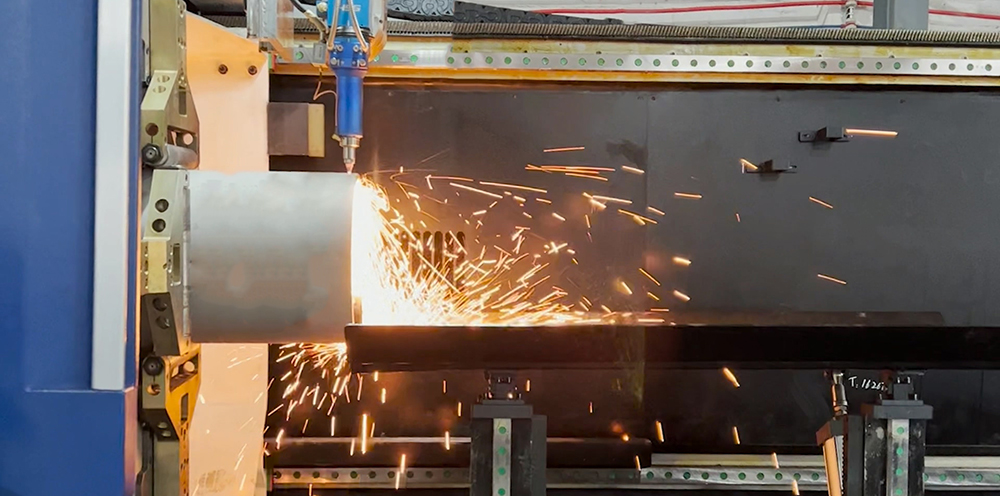

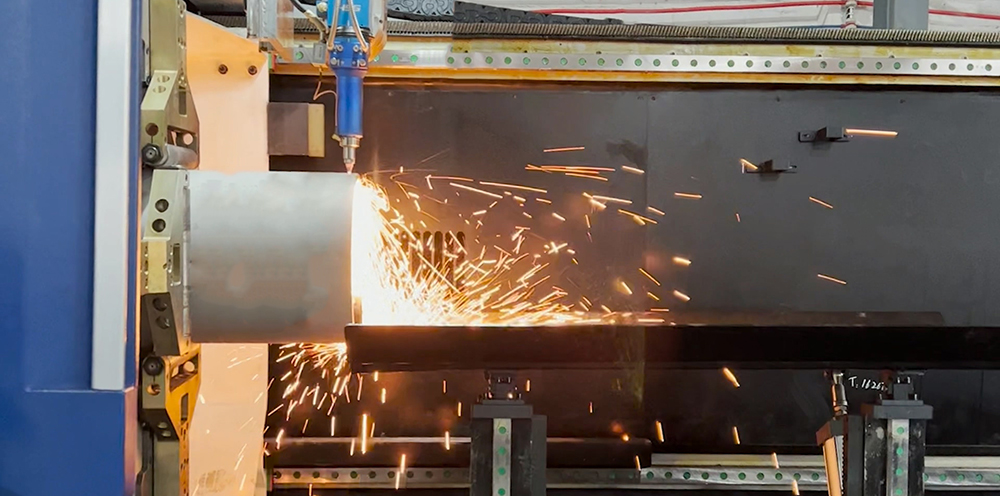

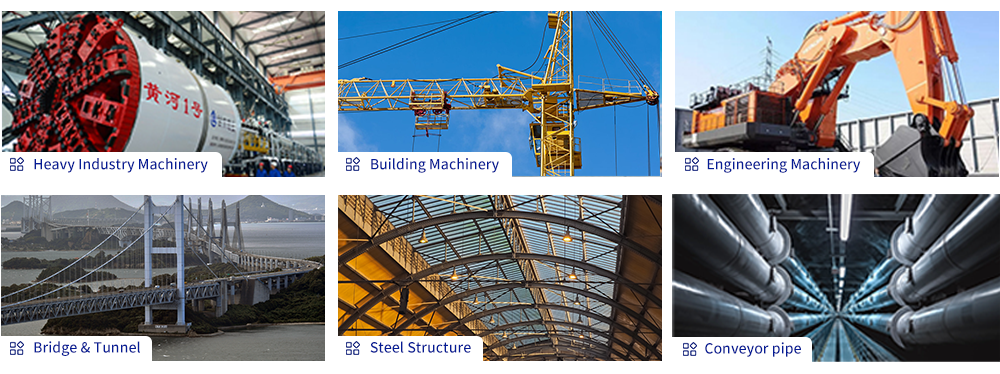

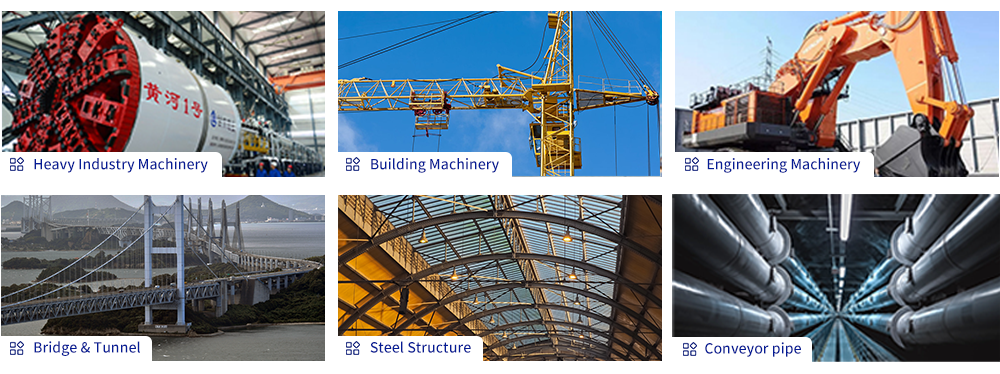

As everyone knows, metal tube application is ubiquitous in modern industrial production. As far as bridge & tunnel, heavy industry machinery, convey piping and steel structures are concerned, processing over-sized and ultra-long heavy tubes is still a huge problem for enterprise production. However, heavy-tube cutting machines available in market are faced with small weight of single tube, low cutting efficiency, long tailing and other questions. In such case, tube processing enterprises are in sore need of more powerful machines on the one hand, and machine manufacturers are also forced to speed up their technical innovation and offer the better solutions on the other hand.

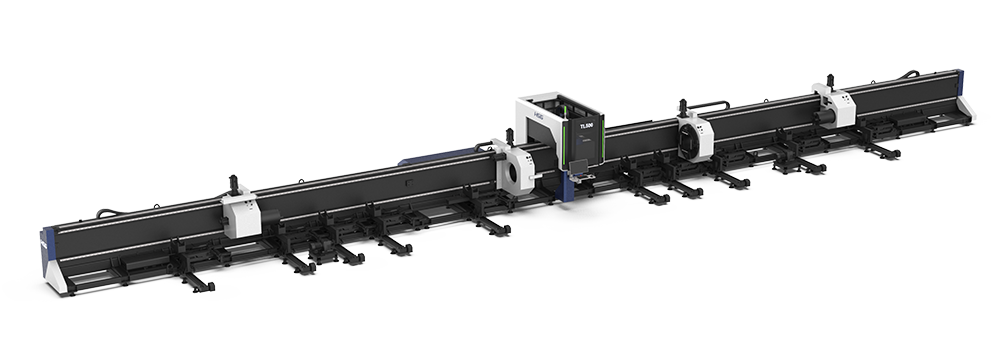

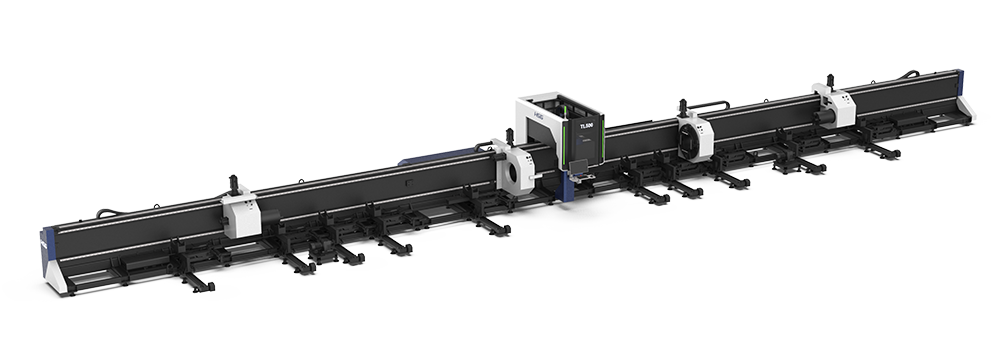

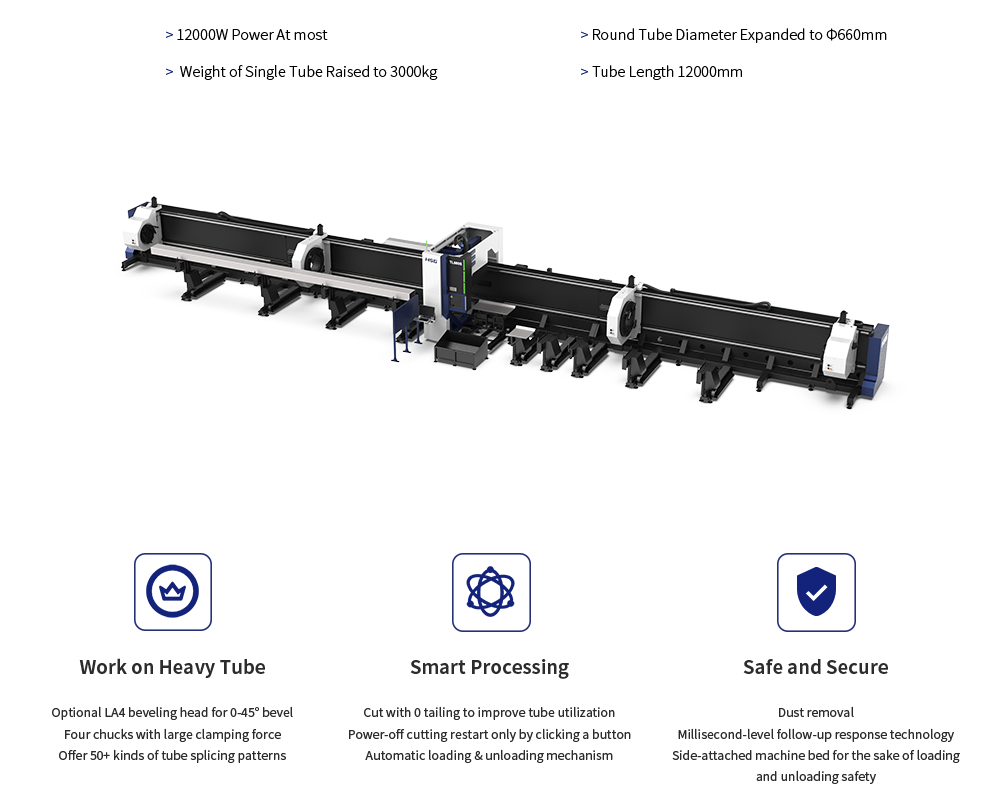

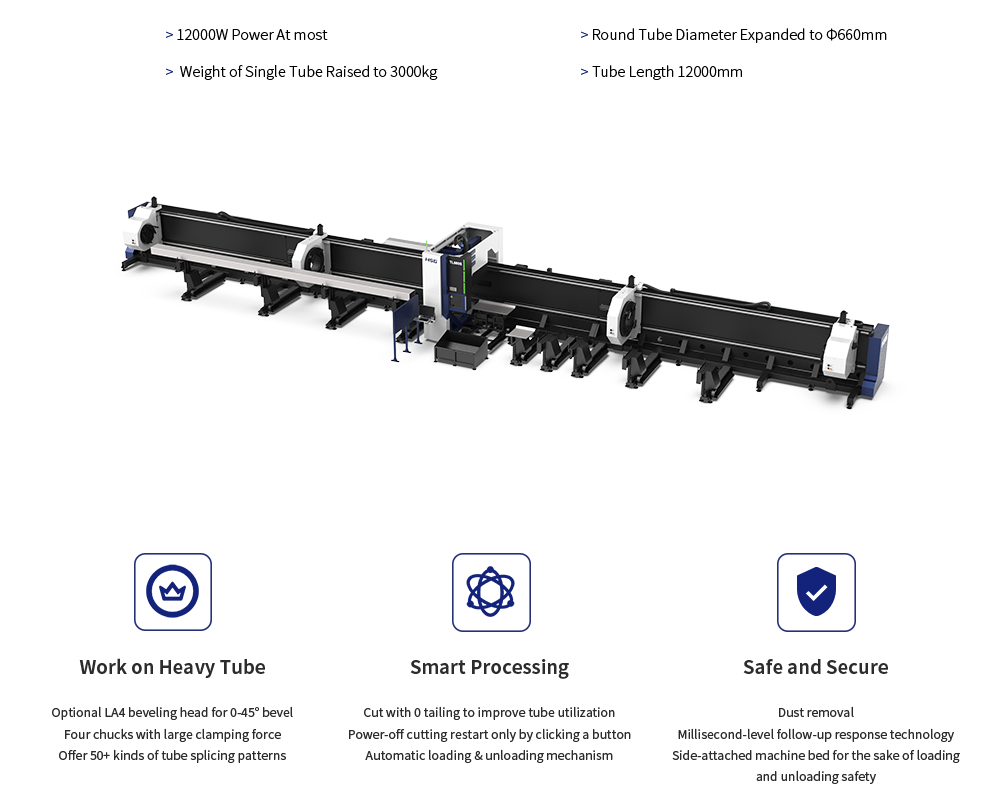

HSG Laser has got down to heavy-tube processing field since 2019 and launched TL500 (four-chuck heavy-duty tube cutting machine) that bears 1.2t single tube. Now, a new member joins in TL series, namely, TL660S, which not only follows TL series’ superiority in four-chuck structure, but also extends heavy tube processing range and takes tube cutting ability & quality to new heights.

HSG Laser has got down to heavy-tube processing field since 2019 and launched TL500 (four-chuck heavy-duty tube cutting machine) that bears 1.2t single tube. Now, a new member joins in TL series, namely, TL660S, which not only follows TL series’ superiority in four-chuck structure, but also extends heavy tube processing range and takes tube cutting ability & quality to new heights.

TL660S

Worthy of Its Name and Value for Money

Applicable Industries

Worthy of Its Name and Value for Money

Applicable Industries

Since the year of 2015 when HSG Laser launched its first tube laser cutting machine, we have always adhered to our role as pathfinder and hammered at technical breakthrough in functions. Through years of efforts, HSG Laser has formed the complete line of tube cutting machines, ranging from small tube (Φ10mm) to large tube (Φ660mm), from light-weight tube (50kg) to heavy tube (3000kg), from straight incision to 0-45° bevel, and from 6000mm tube cutting to 12000mm long tube. These actions reveal HSG Laser’s attentive deployment and ingenious dedication to tube cutting field. We know well that only continuous upgrade and reformation are the key factors to keep pace with the times and metal processing industry.

Sheet Metal Cutting Machine

Sheet Metal Cutting Machine

Tube Metal Cutting Machine

Tube Metal Cutting Machine

Sheet and Tube Cutting Machine

Sheet and Tube Cutting Machine

Thermoforming and Processing

Thermoforming and Processing

Bending Machine

Bending Machine

Handheld Laser Welding Machine

Handheld Laser Welding Machine

Automation Equipment

Automation Equipment

Profiles Laser Cutting Machine

Profiles Laser Cutting Machine