CIIF Shanghai: HSG 3+ Flagship Products Debut, Opening Laser+ Era

Post date: 2023-09-21 11:46:03

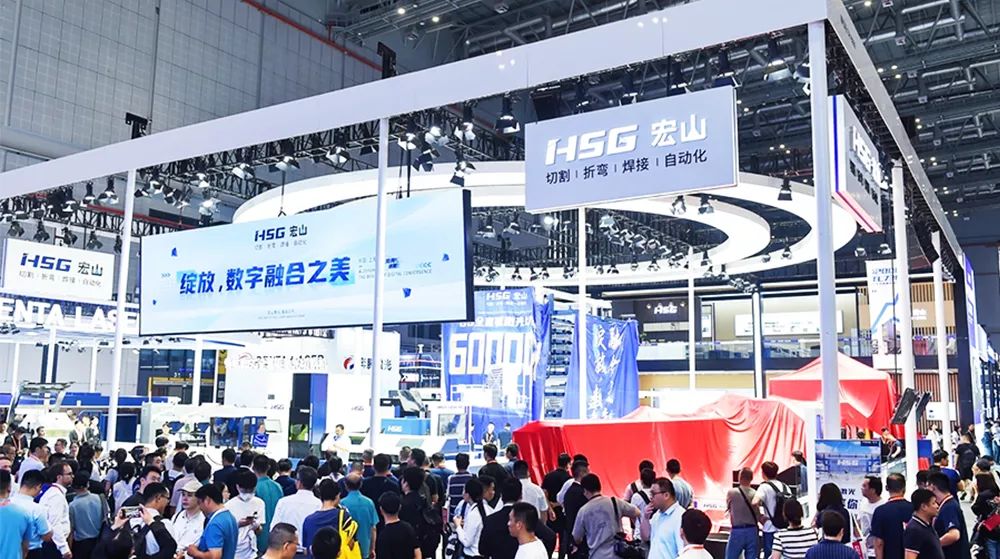

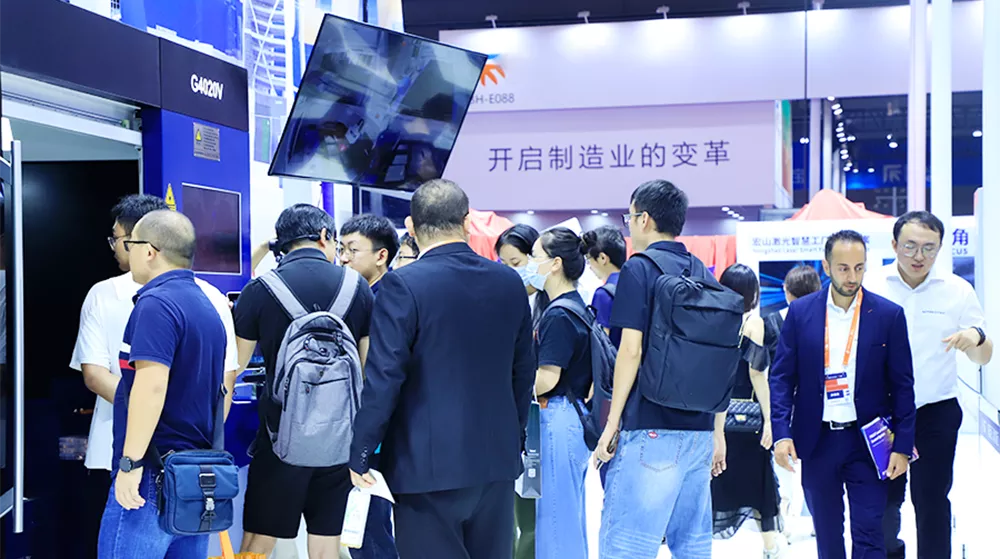

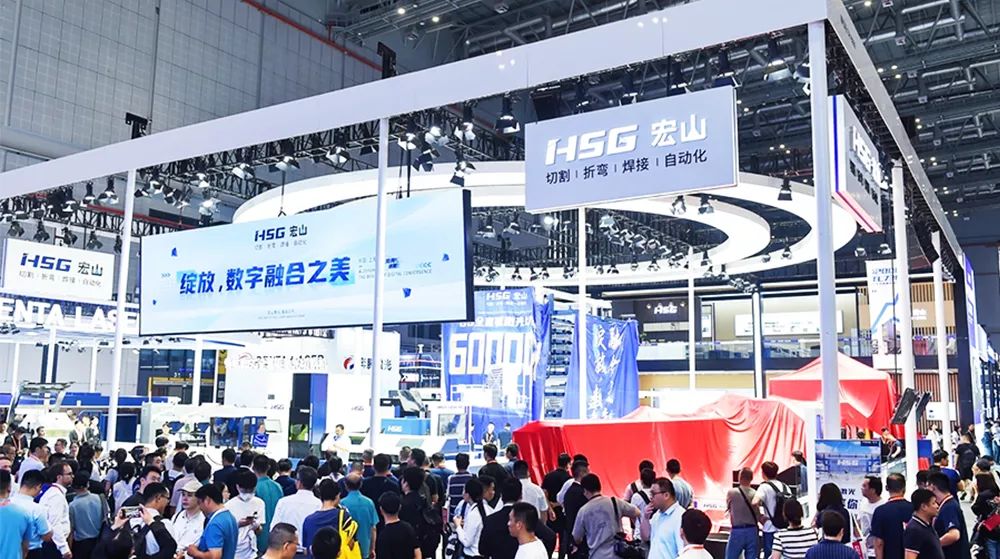

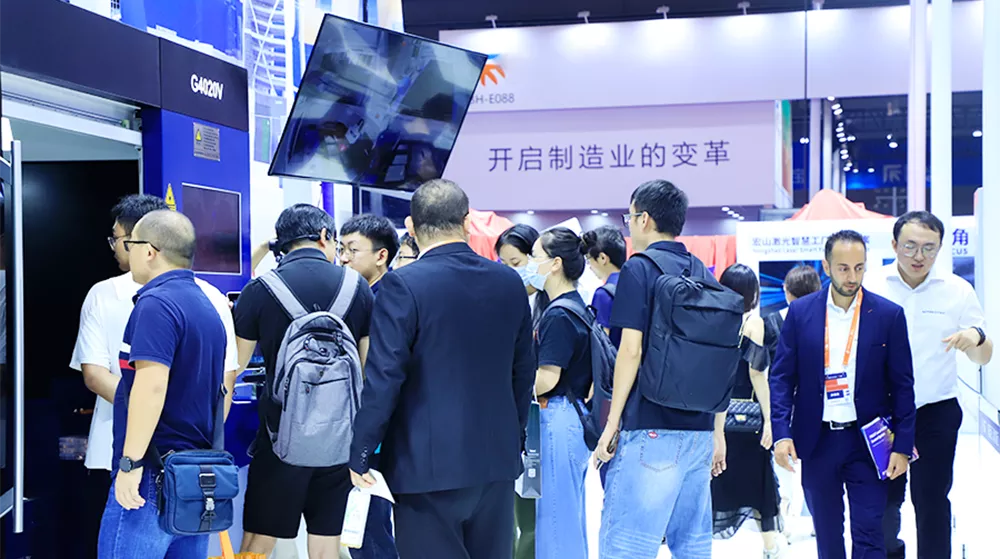

On September 19, after three years' absence, the China International Industry Fair (CIIF), known as the "industrial vindicator", opened at the Shanghai National Convention and Exhibition Center.

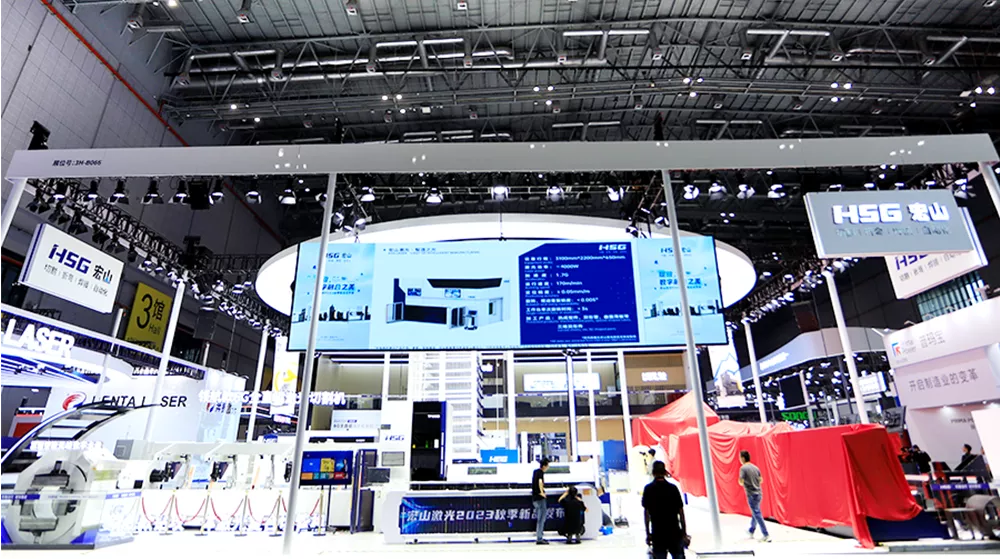

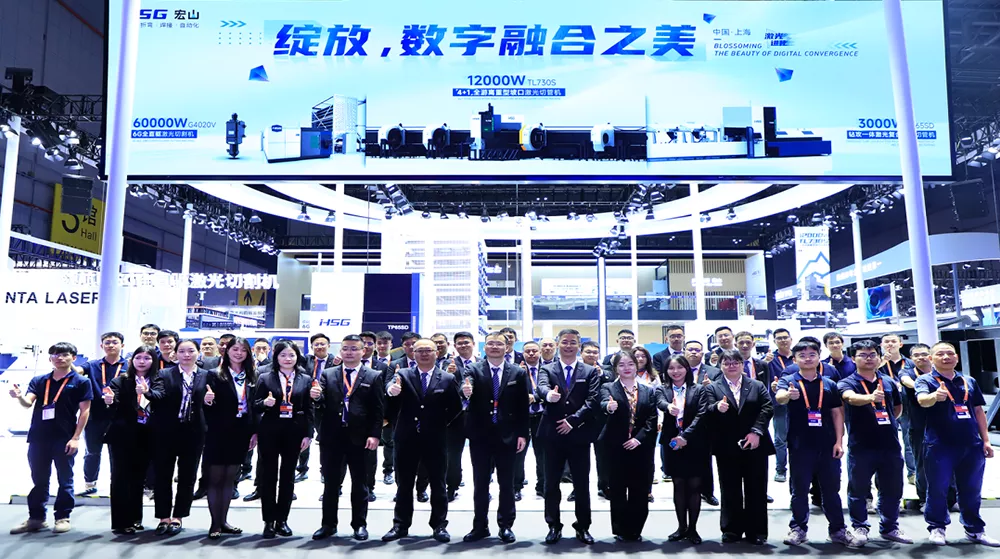

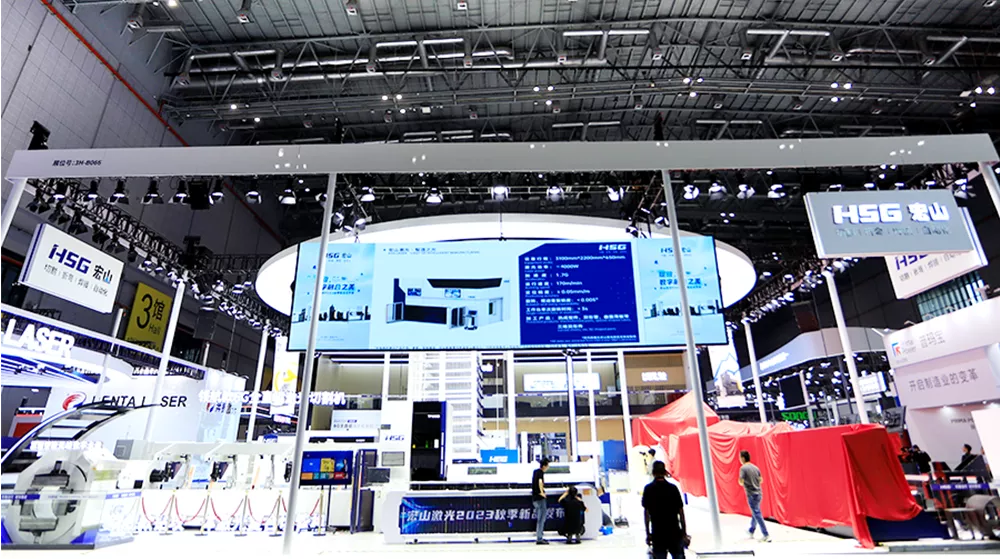

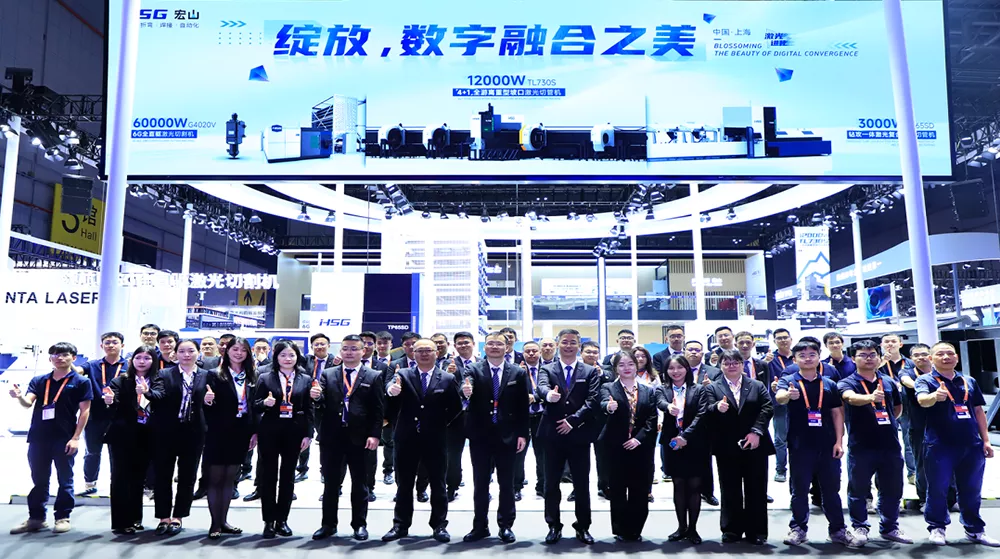

HSG with a number of flagship products made a stunning debut at Shanghai CIIF 3H-B066, attracting widespread attention. For the first day of the grand event, we directly hit the scene.

As an important participant in the domestic laser industry, HSG has participated in the CIIF for many consecutive years. For this exhibition, HSG booth was divided into three distinct areas, showcasing a series of flagship products with unique highlights.

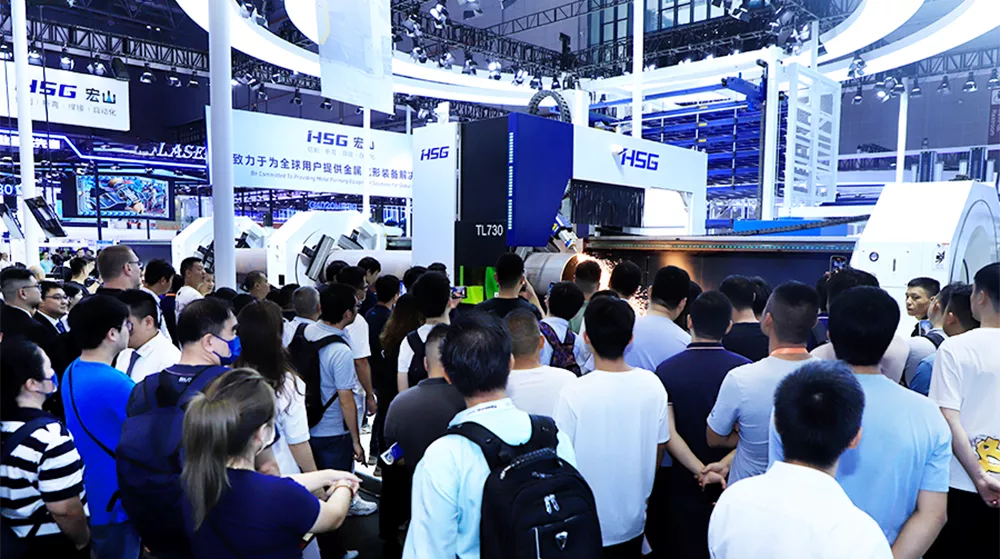

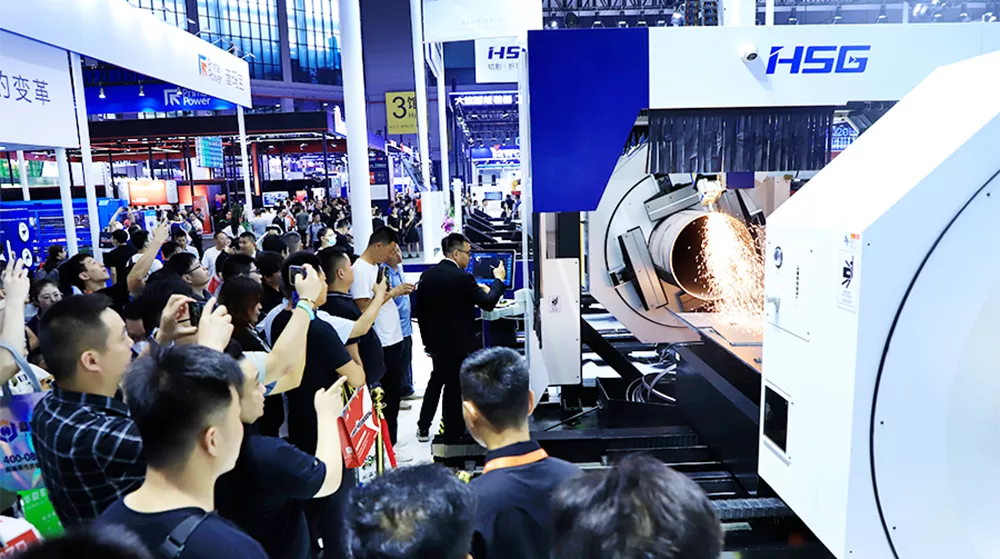

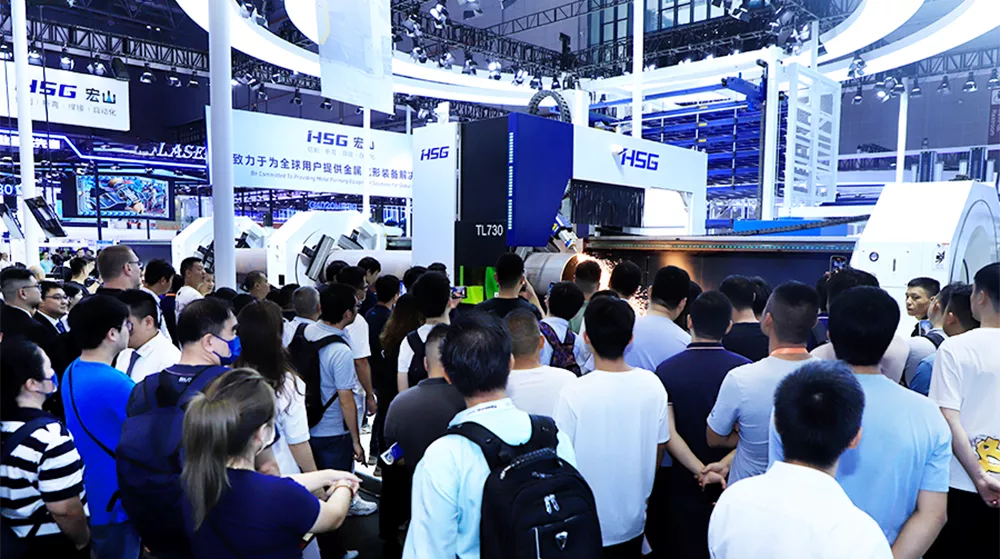

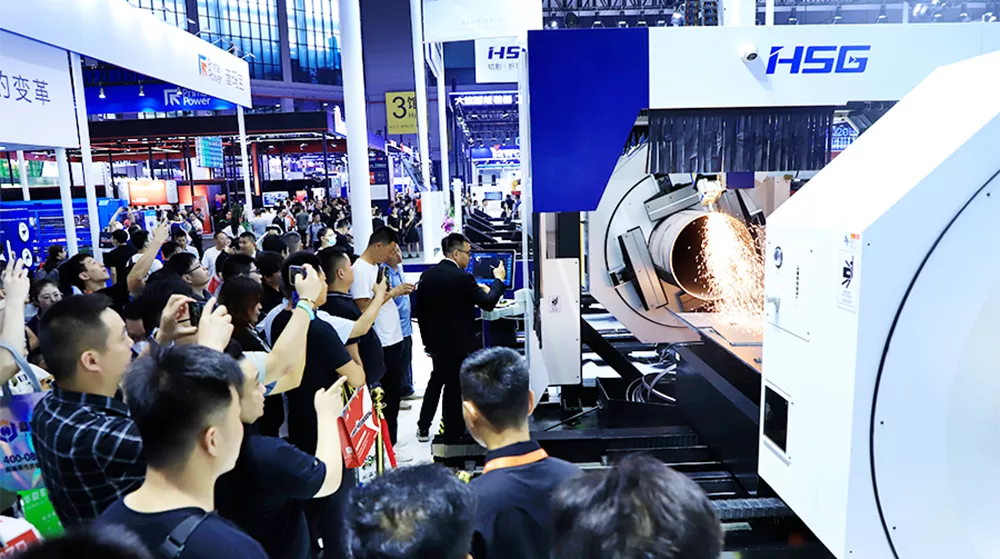

Three representative products - the pilot "4+1" Full-floating Heavy-duty Bevel Tube Laser Cutting Machine TL730S, the pilot 6G Fully-direct Drive Laser Cutting Machine G4020V, and the flagship Drilling-Cutting Integrated Laser Composite Tube Cutting Machine TP65SD - stood out as the center of attention for many industry experts and visitors with their boundary-crossing, innovation-reconstructing technology and product strength. They vividly demonstrated the rich core of the "laser+" era to the audience, becoming the focus of the whole exhibition.

● Laser+ Era, Focusing On Core Technologies

"4+1" Full-floating Heavy Duty Bevel Tube Cutting Machine

HSG continuously improves the ceiling of tube machines and creates the "4+1" fully-detached heavy-duty bevel tube laser cutting machine TL730S.

The innovative "4+1" chuck structure combines C3 and C4 chucks into one for dual support. The loading end is clamped with four points for significant load improvement. The TL730S single tube loading capacity can reach 4 tons, and the maximum processing tube diameter is 715mm.

With 20000W high-power cutting and bevel cutting, the cutting thickness and speed are significantly improved, and the bevel processing can be completed in one pass, saving steps.

● Laser+ Era, Adding Core Performances

6G All-drive Motor Laser Cutting Machine G4020V

As a star series of high-power laser cutting equipment from HSG, the G4020V high-power laser cutting machine adds another layer of strength!

Equipped with XYZ three-axis linear motors, the motors are directly connected to the load, eliminating intermediate links such as reducers, gears, and leadscrews, effectively avoiding issues such as backlash, inertia, and friction in the transmission system. It can easily achieve 6G acceleration and a maximum speed of 300m/min in empty movement.

The German Rexroth guide rail adopts a double-sided four-rail structure with high stiffness, high load capacity, and reliable stability.

The hydraulic lifting and exchange system features single-side exchange, with the workbench closer to the exhaust port for better exhaust performance. The exchange system has no height difference between the upper and lower tables, so the Z-axis cutting head does not need to move down too much for cutting, ensuring the stability of the Z-axis components during high-speed cutting.

● Laser+ Era, Compositing Core Process

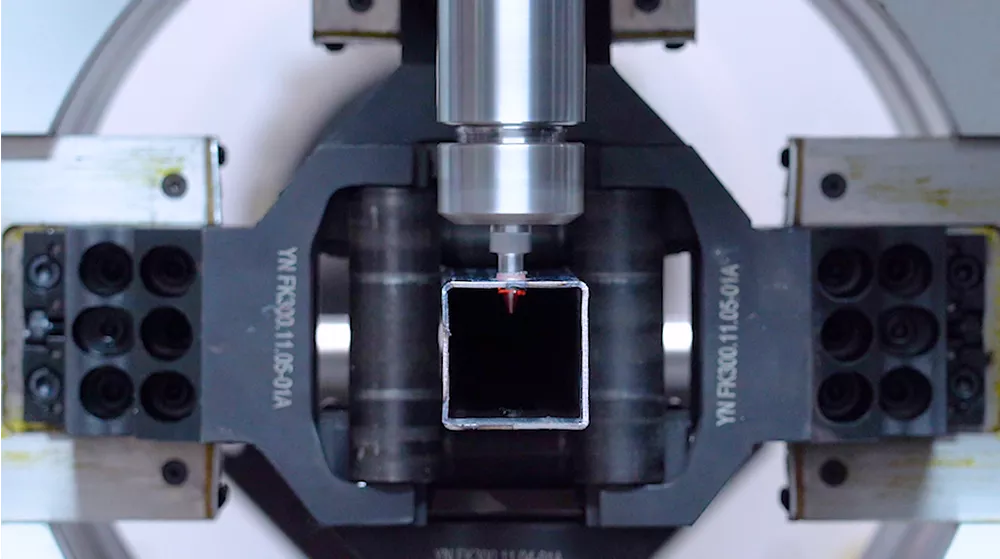

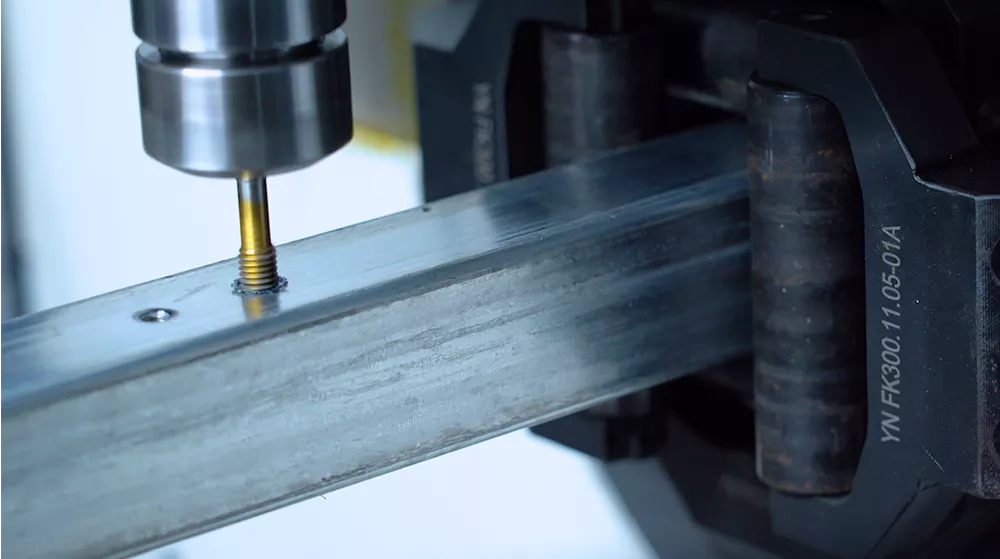

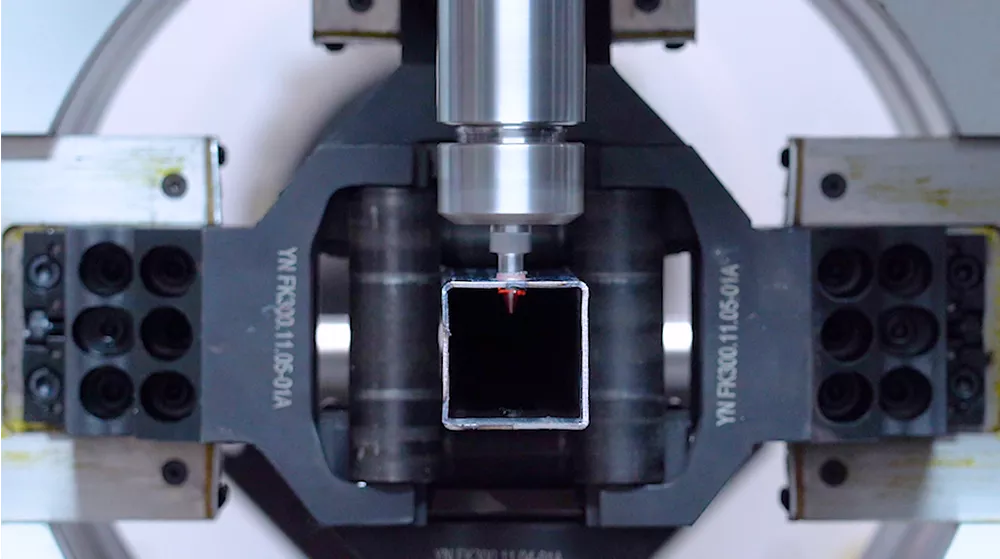

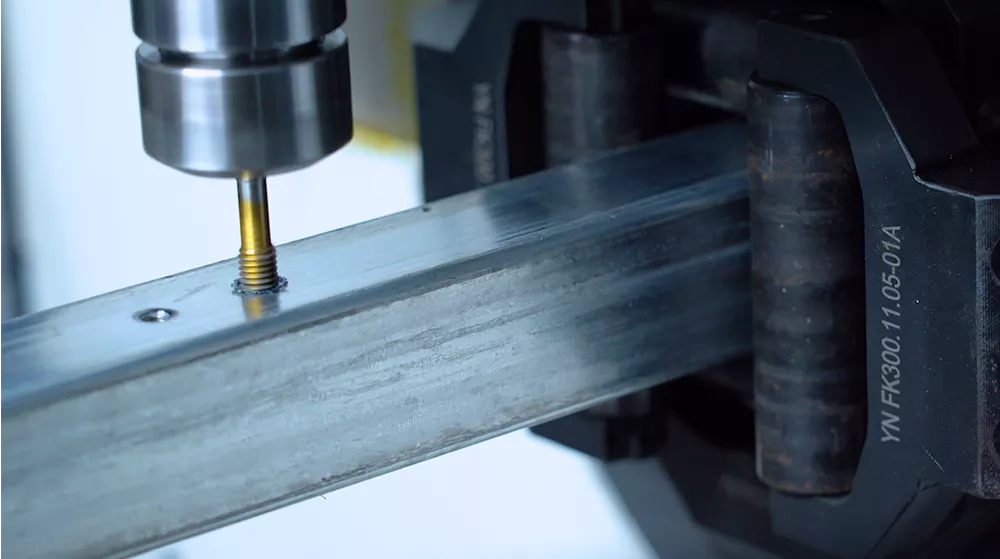

Drilling-Cutting-Tapping Laser Composites Tube Cutting Machine TP65SD

Drilling and tapping laser composite tube cutting machine TP65SD, with its strength, tells you that the boundary of laser is not only limited to cutting and welding.

A TP65SD tube cutting machine integrates the functions of laser cutting, thermal drilling, and tapping to achieve a single-piece molding. It can also achieve exquisite 45° angle bevel cutting, reducing processing steps, saving labor, greatly reducing processing time and improving production efficiency.

Equipped with SPEED+ high-speed cutting technology, the maximum acceleration can reach 1.2G, and the chuck speed can reach 120r/min, greatly improving the cutting efficiency of dense small graphics.

The era of laser + evolution is an era that promotes development through openness, and the "+" symbolizes infinite possibilities.

We believe that the future of laser mother machines will combine industry insiders and outsiders to create new ecosystems in new fields.

HSG with a number of flagship products made a stunning debut at Shanghai CIIF 3H-B066, attracting widespread attention. For the first day of the grand event, we directly hit the scene.

As an important participant in the domestic laser industry, HSG has participated in the CIIF for many consecutive years. For this exhibition, HSG booth was divided into three distinct areas, showcasing a series of flagship products with unique highlights.

Three representative products - the pilot "4+1" Full-floating Heavy-duty Bevel Tube Laser Cutting Machine TL730S, the pilot 6G Fully-direct Drive Laser Cutting Machine G4020V, and the flagship Drilling-Cutting Integrated Laser Composite Tube Cutting Machine TP65SD - stood out as the center of attention for many industry experts and visitors with their boundary-crossing, innovation-reconstructing technology and product strength. They vividly demonstrated the rich core of the "laser+" era to the audience, becoming the focus of the whole exhibition.

● Laser+ Era, Focusing On Core Technologies

"4+1" Full-floating Heavy Duty Bevel Tube Cutting Machine

HSG continuously improves the ceiling of tube machines and creates the "4+1" fully-detached heavy-duty bevel tube laser cutting machine TL730S.

The innovative "4+1" chuck structure combines C3 and C4 chucks into one for dual support. The loading end is clamped with four points for significant load improvement. The TL730S single tube loading capacity can reach 4 tons, and the maximum processing tube diameter is 715mm.

With 20000W high-power cutting and bevel cutting, the cutting thickness and speed are significantly improved, and the bevel processing can be completed in one pass, saving steps.

● Laser+ Era, Adding Core Performances

6G All-drive Motor Laser Cutting Machine G4020V

As a star series of high-power laser cutting equipment from HSG, the G4020V high-power laser cutting machine adds another layer of strength!

Equipped with XYZ three-axis linear motors, the motors are directly connected to the load, eliminating intermediate links such as reducers, gears, and leadscrews, effectively avoiding issues such as backlash, inertia, and friction in the transmission system. It can easily achieve 6G acceleration and a maximum speed of 300m/min in empty movement.

The German Rexroth guide rail adopts a double-sided four-rail structure with high stiffness, high load capacity, and reliable stability.

The hydraulic lifting and exchange system features single-side exchange, with the workbench closer to the exhaust port for better exhaust performance. The exchange system has no height difference between the upper and lower tables, so the Z-axis cutting head does not need to move down too much for cutting, ensuring the stability of the Z-axis components during high-speed cutting.

● Laser+ Era, Compositing Core Process

Drilling-Cutting-Tapping Laser Composites Tube Cutting Machine TP65SD

Drilling and tapping laser composite tube cutting machine TP65SD, with its strength, tells you that the boundary of laser is not only limited to cutting and welding.

A TP65SD tube cutting machine integrates the functions of laser cutting, thermal drilling, and tapping to achieve a single-piece molding. It can also achieve exquisite 45° angle bevel cutting, reducing processing steps, saving labor, greatly reducing processing time and improving production efficiency.

Equipped with SPEED+ high-speed cutting technology, the maximum acceleration can reach 1.2G, and the chuck speed can reach 120r/min, greatly improving the cutting efficiency of dense small graphics.

The era of laser + evolution is an era that promotes development through openness, and the "+" symbolizes infinite possibilities.

We believe that the future of laser mother machines will combine industry insiders and outsiders to create new ecosystems in new fields.

Sheet Metal Cutting Machine

Sheet Metal Cutting Machine

Tube Metal Cutting Machine

Tube Metal Cutting Machine

Sheet and Tube Cutting Machine

Sheet and Tube Cutting Machine

Thermoforming and Processing

Thermoforming and Processing

Bending Machine

Bending Machine

Handheld Laser Welding Machine

Handheld Laser Welding Machine

Automation Equipment

Automation Equipment

Profiles Laser Cutting Machine

Profiles Laser Cutting Machine