HSG Flexible Production Line Delivered to Indian Air Conditioning Manufacturer

Post date: 2022-11-22 15:38:21

"It is well known that most regions of India are located in tropical zone. In summer, air temperature is usually high, even reaching 50°. Therefore, local demands for commercial and domestic air conditioning units are increasing day by day. We estimate that sales volume of air conditioner will grow substantially in first, second- and third-tier cities in following years. It can be said that Indian market has huge potentials." A spokesman of an Indian air conditioning manufacturer said optimistically as above.

WA Company, founded in 1997 and located in Rajasthan, India, is one of influential leading enterprises in Indian air conditioning industry as a result of CNY 0.4 billion of yearly output value.

Irrespective of its existing traditional metal processing machines like punching machines and CO2 cutting machines, WA was still insufficient to cope with orders uprush and decided to appeal to more efficient metal processing solutions. Through extensive comparison with other world-class brands, WA decidedly purchased a complete set of flexible laser production line from HSG Laser for the processing of air conditioner housing, chassis and electric cabinet as well as various spare parts, such as, air ducts, air handling units, air washer and cooling coils. As thus, its production line will be upgraded to automatic style, which liberates its labor force and boosts yearly capacity.

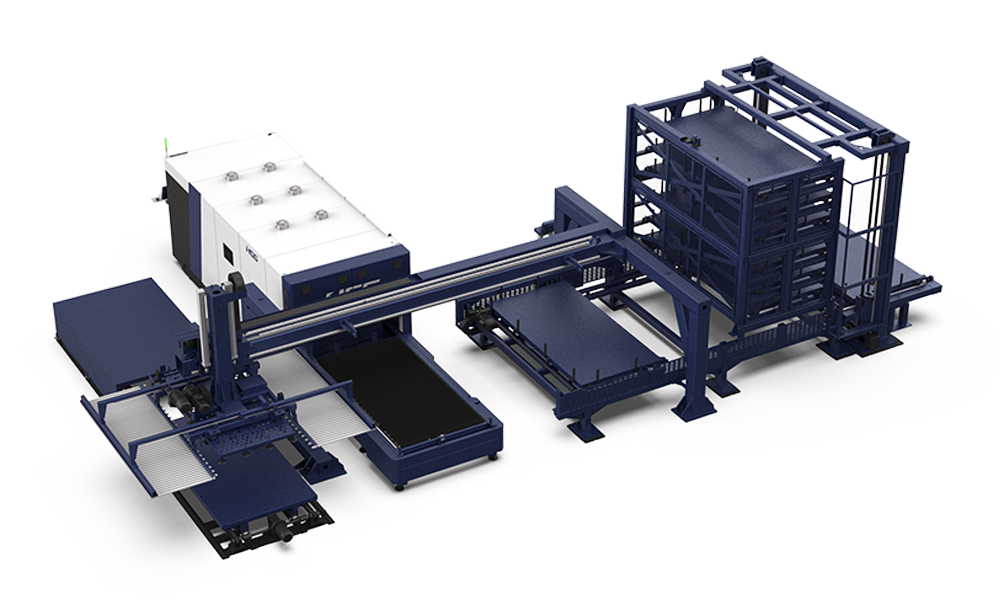

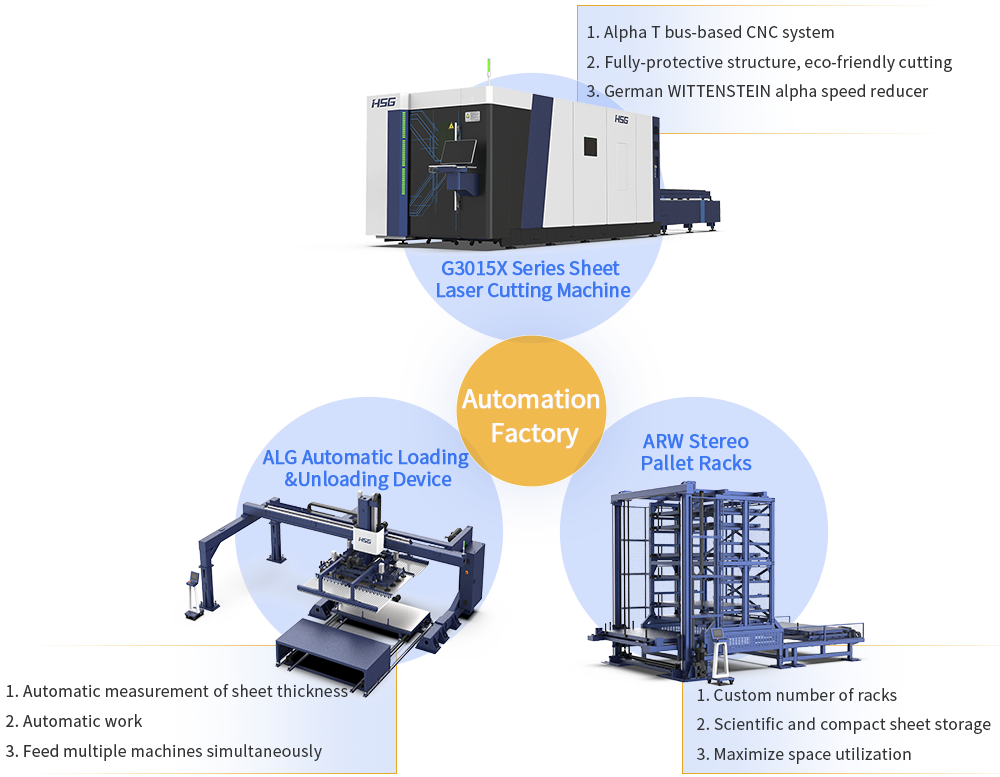

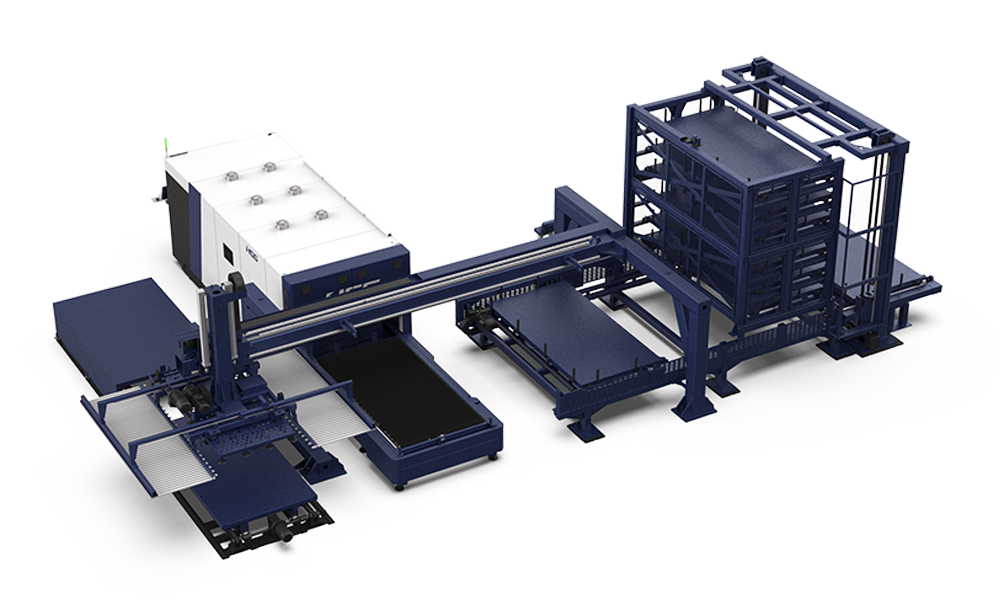

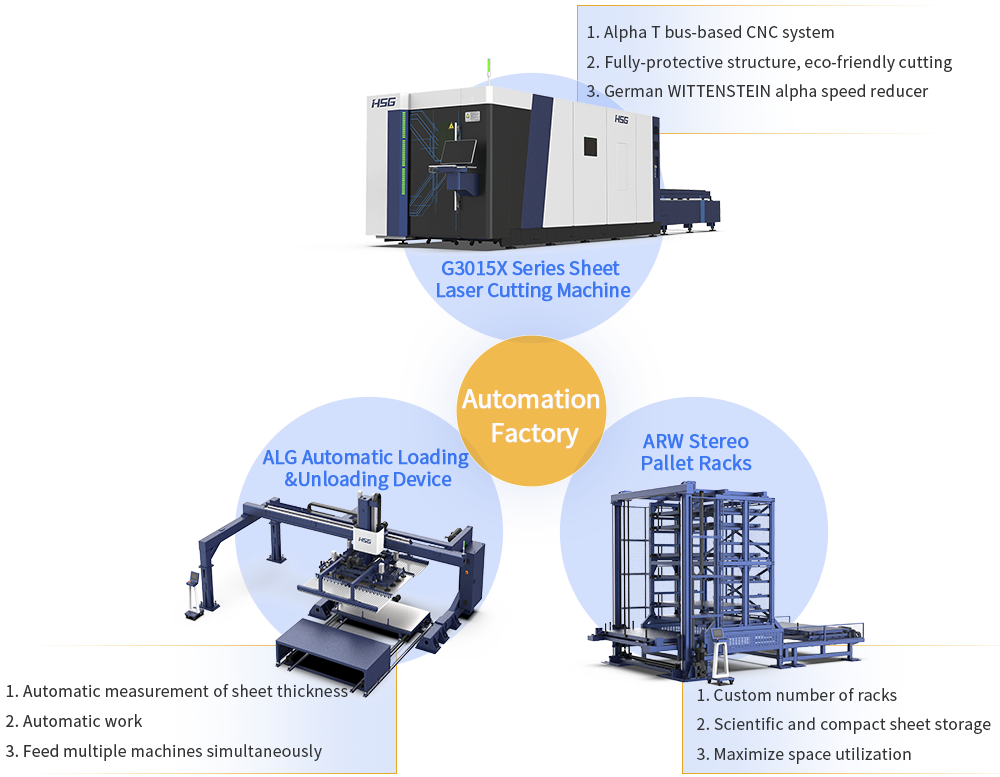

The production line is made of sheet laser cutting machine, automatic loading & unloading device and stereo pallet racks for cutting, loading, unloading and storing sheet metals. Among these, Alpha T bus CNC system self-developed by HSG Laser can take integrated controlling and scheduling of other devices as the core "brain". With that, 7*24h uninterrupted work is made possible and production efficiency is maximized.

To deliver this production line to WA as soon as possible, HSG Laser proactively asked its production department and workers to fulfill the production task against time. In other words, actual delivery was much ahead of its lead time agreed. A few days ago, the line arrived at India port and came into service after WA's careful testing and inspection. Even managers in charge gave it a thumb up after test run. Henceforth, WA would enjoy intelligent control, intelligent production and intelligent transfer due to HSG flexible production line and march towards Industry 4.0 Era at top speed.

To effectuate automated work, Industry 4.0 gives priority to intelligent manufacturing and combines traditional production with internet technology. Since the date when Germany put forward the concept of Industry 4.0, it has swept across the globe and been followed eagerly by world-wide enterprises in particular manufacturing firms. As a provider of hi-tech laser forming solutions, HSG Laser keeps up with the trend of global industry all the time to not only bear laser processing intellectualization, automation and customization in mind, but also put into real action just for the sake of serving global metal processing customers with complete set of metal forming solutions.

WA Company, founded in 1997 and located in Rajasthan, India, is one of influential leading enterprises in Indian air conditioning industry as a result of CNY 0.4 billion of yearly output value.

Irrespective of its existing traditional metal processing machines like punching machines and CO2 cutting machines, WA was still insufficient to cope with orders uprush and decided to appeal to more efficient metal processing solutions. Through extensive comparison with other world-class brands, WA decidedly purchased a complete set of flexible laser production line from HSG Laser for the processing of air conditioner housing, chassis and electric cabinet as well as various spare parts, such as, air ducts, air handling units, air washer and cooling coils. As thus, its production line will be upgraded to automatic style, which liberates its labor force and boosts yearly capacity.

The production line is made of sheet laser cutting machine, automatic loading & unloading device and stereo pallet racks for cutting, loading, unloading and storing sheet metals. Among these, Alpha T bus CNC system self-developed by HSG Laser can take integrated controlling and scheduling of other devices as the core "brain". With that, 7*24h uninterrupted work is made possible and production efficiency is maximized.

To deliver this production line to WA as soon as possible, HSG Laser proactively asked its production department and workers to fulfill the production task against time. In other words, actual delivery was much ahead of its lead time agreed. A few days ago, the line arrived at India port and came into service after WA's careful testing and inspection. Even managers in charge gave it a thumb up after test run. Henceforth, WA would enjoy intelligent control, intelligent production and intelligent transfer due to HSG flexible production line and march towards Industry 4.0 Era at top speed.

To effectuate automated work, Industry 4.0 gives priority to intelligent manufacturing and combines traditional production with internet technology. Since the date when Germany put forward the concept of Industry 4.0, it has swept across the globe and been followed eagerly by world-wide enterprises in particular manufacturing firms. As a provider of hi-tech laser forming solutions, HSG Laser keeps up with the trend of global industry all the time to not only bear laser processing intellectualization, automation and customization in mind, but also put into real action just for the sake of serving global metal processing customers with complete set of metal forming solutions.

Sheet Metal Cutting Machine

Sheet Metal Cutting Machine

Tube Metal Cutting Machine

Tube Metal Cutting Machine

Sheet and Tube Cutting Machine

Sheet and Tube Cutting Machine

Thermoforming and Processing

Thermoforming and Processing

Bending Machine

Bending Machine

Handheld Laser Welding Machine

Handheld Laser Welding Machine

Automation Equipment

Automation Equipment

Profiles Laser Cutting Machine

Profiles Laser Cutting Machine