W

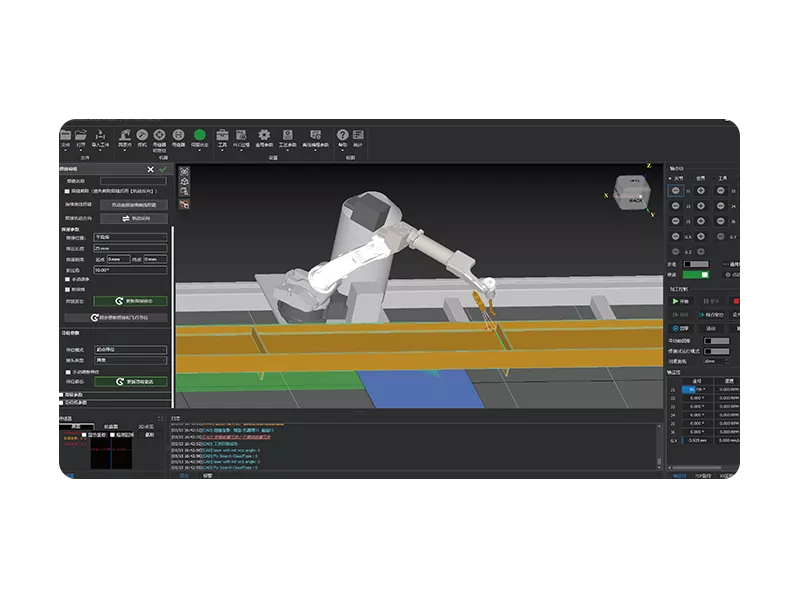

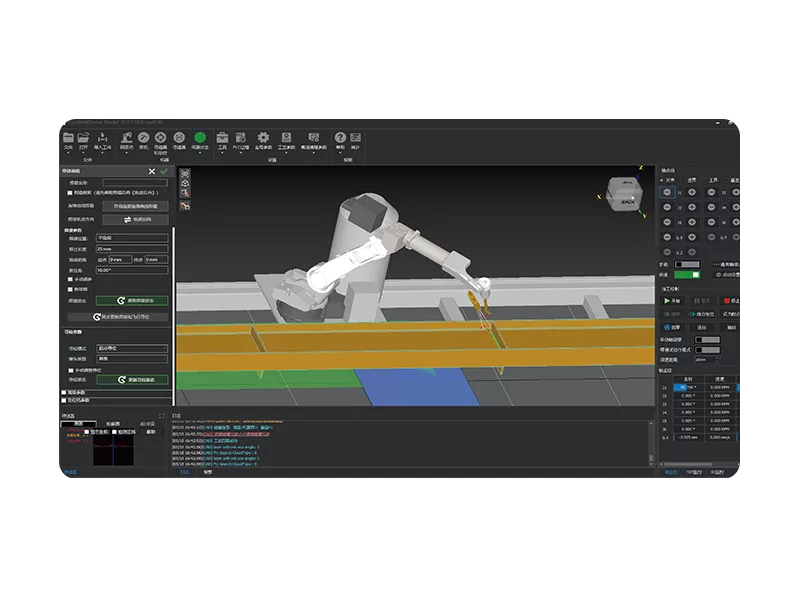

Offline Simulation

HSG Composite Vision Technology

Digital Twin Technology

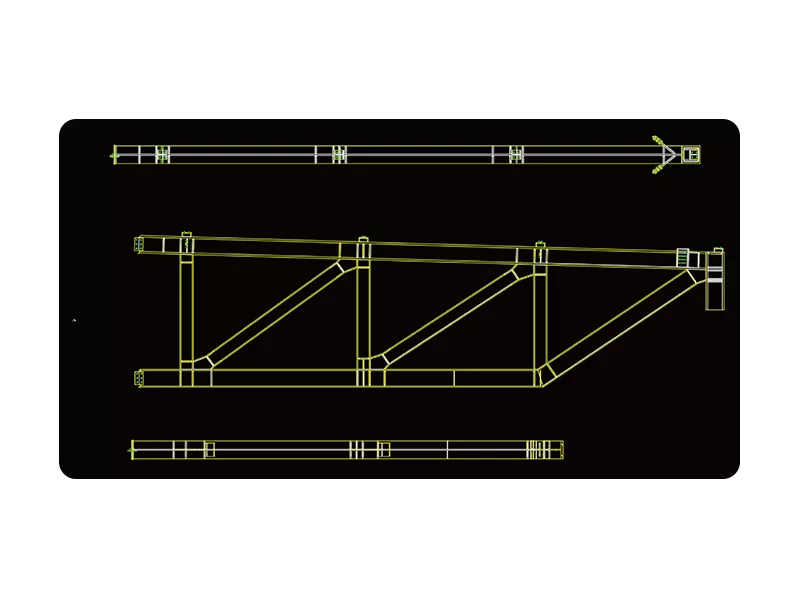

Support Welding of Various Steel Structure Products

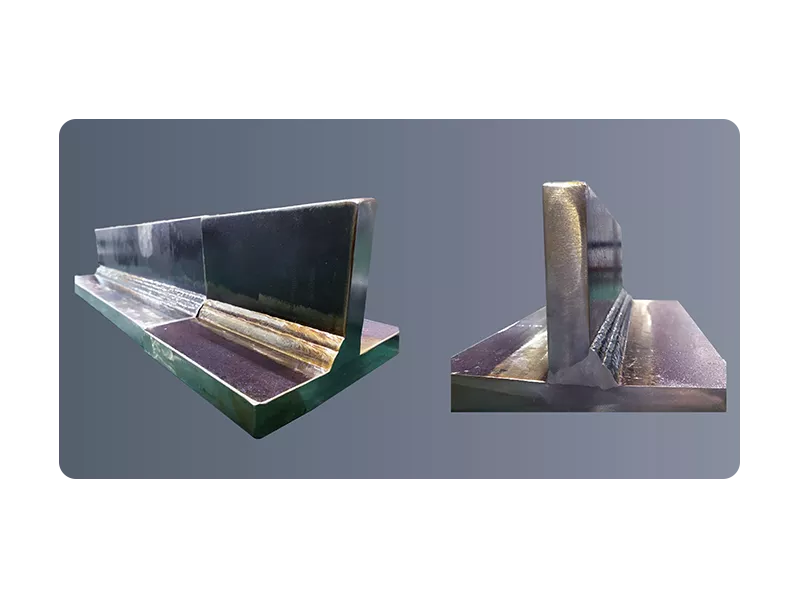

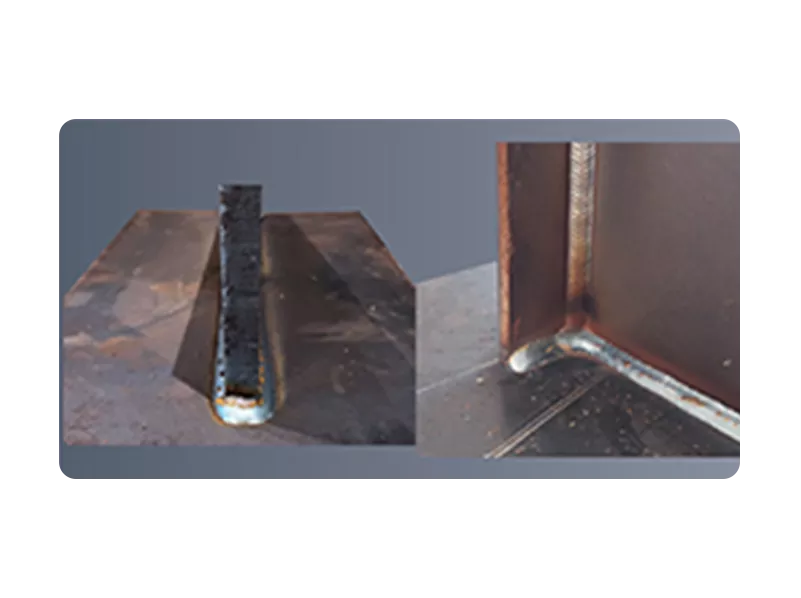

Multi-layer and Multi-pass Welding

Fillet Welding & Continuous Welding

w

Technical Parameters

- Model

- Operating System

- Dimensions-Single Machine(L*W*H)

- Applicable Workpiece Specifications

- Welding Material

- Welding Thickness

Sheet Metal Cutting Machine

Sheet Metal Cutting Machine

Tube Metal Cutting Machine

Tube Metal Cutting Machine

Sheet and Tube Cutting Machine

Sheet and Tube Cutting Machine

Thermoforming and Processing

Thermoforming and Processing

Bending Machine

Bending Machine

Handheld Laser Welding Machine

Handheld Laser Welding Machine

Automation Equipment

Automation Equipment

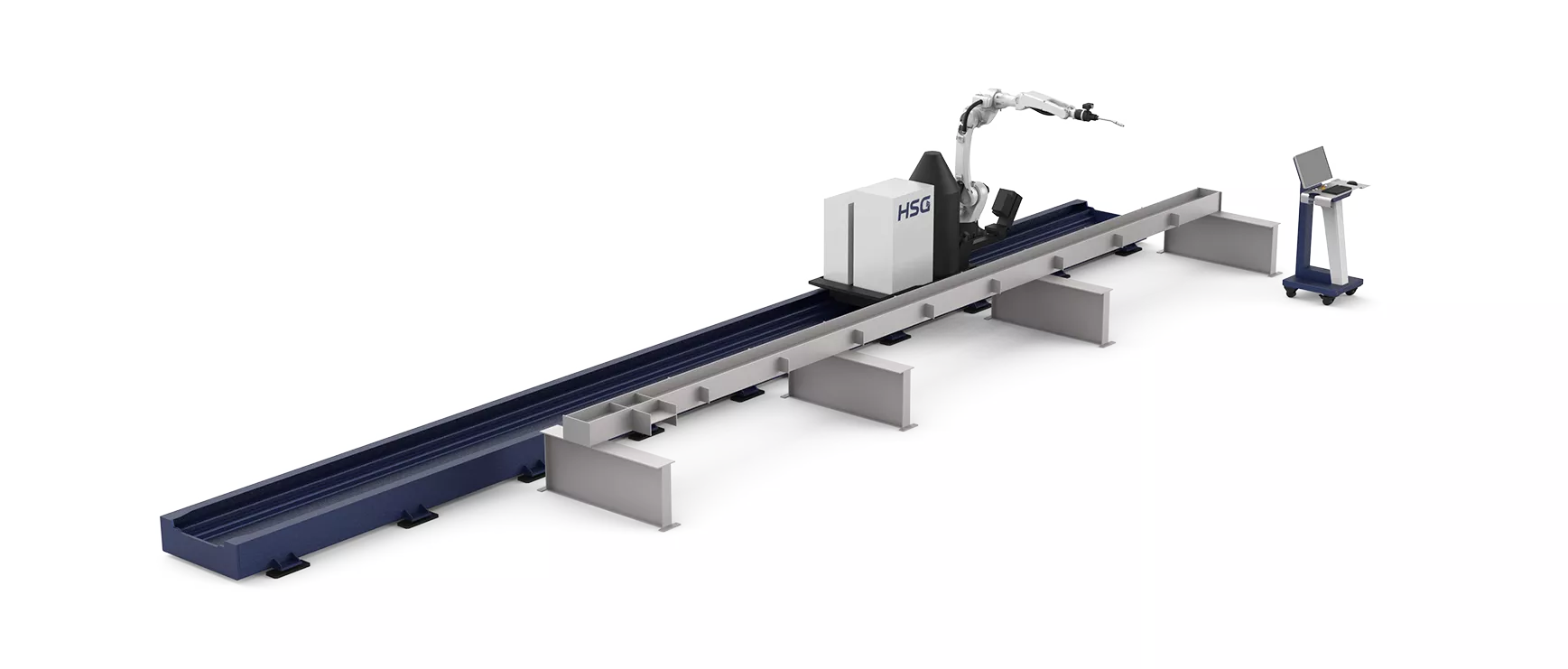

Profiles Laser Cutting Machine

Profiles Laser Cutting Machine