Cut, Drill, Tap – All in one go

your ultimate solution for precision tube processing

-

![]() Cut, drill, tap – all in one

Cut, drill, tap – all in one

-

![]() 1.2G acceleration peak productivity

1.2G acceleration peak productivity

-

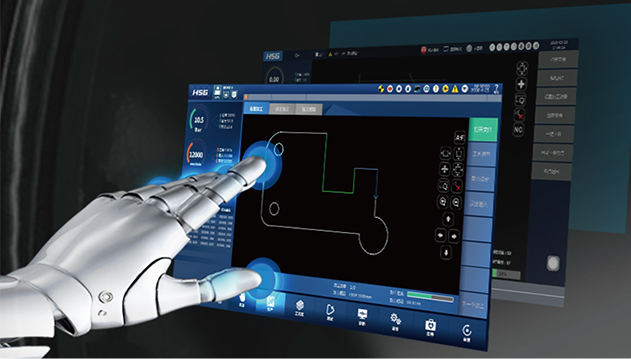

![]() Extensive smart applications

Extensive smart applications

-

![]() ±45° high-quality bevel cuts

±45° high-quality bevel cuts

-

![]() SPEED+ rapid cutting

SPEED+ rapid cutting

-

![]() High-precision smart chuck

High-precision smart chuck

![]() Designed in Japan

Designed in Japan

In 2018, HSG established its Global R&D Center in Kanagawa, Tokyo. The center works closely with professors from Chiba University, to jointly research the latest laser optics applications and improve the precision and efficiency of laser processing. This enables HSG to provide customers with more efficient and reliable laser processing technology.

![]() The flagship family – HSG Himalaya Series

The flagship family – HSG Himalaya Series

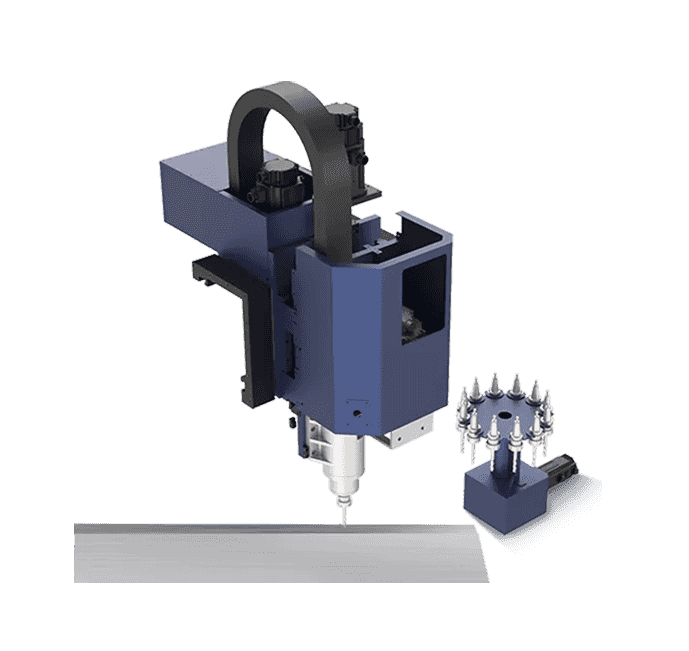

Introducing the TPSD, a flagship product from our himalaya series. TP65SD is an integrated laser tube cutting and drilling machine, offering high-speed, precise cutting, automated loading/unloading, and intelligent features for diverse industrial applications.

One machine, endless possibilities

your productivity and cost-effectiveness all-in-one solution

Cutting

Drilling

Tapping

Transforming pipe processing with innovation

maximizing your pipe processing efficiency & quality through cutting-edge innovation

Enhances your welding and assembly quality

up to ±45° bevel laser tube cutting . drill, tap integrated

Designed For All-in-one Production

Revolutionizing Your Tube Cutting Experience with Integrated Technology

Redefine efficiency : seamlessly integration

HSG multi-aperture thermal drilling-tapping technology

• Boost efficiency: merge cutting and drilling processes

into one seamless

operation, significantly speeding up production.

• Precision and quality: achieve superior precision and

consistency with

laser-powered thermal drilling, enhancing overall product

quality.

• Cost savings: reduce the need for multiple machines and

lower capital

expenditures with our integrated solution.

• Simplified operation: easy-to-use features reduce

training time and streamline

manufacturing processes.

• Protect your materials: our non-contact laser technology

ensures no mechanical

stress or deformation, preserving material integrity.

Unleash speed & precision

HSG multi-aperture thermal drilling-tapping technology

| Spindle speed |

250r/min ~ 2800r/min |

| Tool magazine |

12-positions |

| Thermal drill bit diameter range |

Φ3.7mm ~ Φ14.8mmCarbon steel, stainless steel Suggested thickness: ≤3mm. |

| Overlap range |

M4 ~ M16Carbon steel, stainless steel Suggested thickness: ≤8mm. |

Maximizing stability with intelligent design

HSG intelligent digital chuck with wireless feedback, forming the closed-loop control system

Intelligent self-centering

The collet chucks position and hold your tubes in place without damaging the materials. The self-centering collet chuck with continuous sensor monitoring adapts to every tube geometry. This means you benefit from high part precision.

Precise & durability

Precision clamping with long-lasting durability. Each component is meticulously selected and engineered for excellence, with all mating surfaces featuring dust protection to ensure optimal performance.

Safe and reliable

High safety and reliability. All components are tested using industry-standard clamping force testing equipment, and all accessories comply with industry standards.

Rapid & quality, wide range cutting

committed to driving your high-speed growth

120r/min

Chuck Rotation Speed

140m/min

Max.Traveling Speed

1.2G

Max.Acceleration Speed

200kg

Max.single Tube Weight

12-273mm

Max.Diameter Round Pipe

12*12~200*200mm

Square Pipe Processing Range

Unlock a major boost in productivity for your operations

HSG SPEED+ rapid tube cutting technology

HSG SPEED+ rapid cutting technology

Significantly enhances the efficiency of cutting dense and intricate patterns, ensuring fast and precise tube processing. This cutting-edge technology delivers exceptional performance for high-speed tube cutting, optimizing both throughput and precision for the most demanding applications.

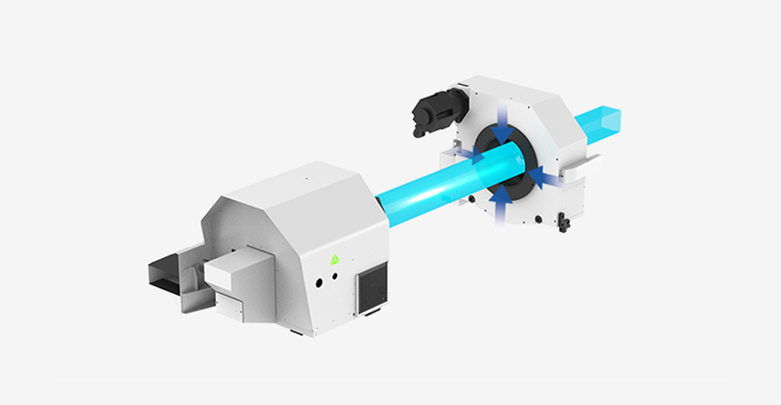

Precision, efficiency, and quality in every Cut

HSG LA4 five-axis tube beveling head

±45° | 20kW

±45° | 20kW

Experience the high-performance bevel cutting head designed for high-power

laser tube cutting

machines. Essential for heavy-duty tube cutting applications.

• Optimized laser resonator:utilizes HSG Japan’s exclusive

optical module design to

maximize laser efficiency.

• Superior thick plate cutting:unique optical path

arrangement significantly

reduces material quality requirements, ensuring high-quality cuts.

• Precision focus control:fully automatic servo motor focus

control for precise and

consistent cutting performance.

• Anti-collision oscillating design:enhanced processing

efficiency and collision

avoidance for uninterrupted operation.

• Modular design:simplifies maintenance, reducing downtime

and costs.

• Versatile bevel cutting:flexible cutting within a ±45°

bevel range, perfect for

complex geometries.

Rapid & quality, wide range cutting

committed to driving your high-speed growth

Comprehensive pipe machine application assistance covering essential operations

Professional pipe cutting process database with years of accumulated data

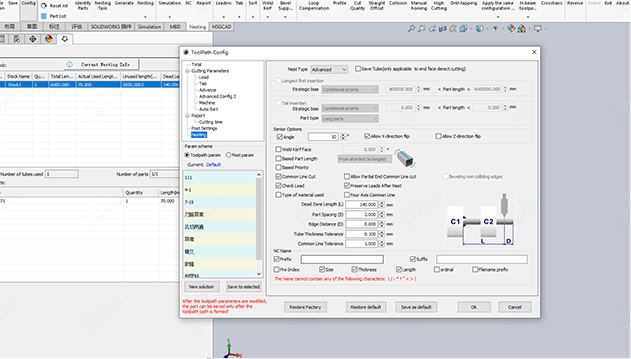

Maximize your production efficiency with intelligent nesting and precise cost control

TPSD Series equipped with the tailor made TTN (Japan) nesting software, this system offers intelligent nesting capabilities that streamline cost estimation and enhance production schedule management.

TPSD Series

- Model

- Power

- Rotating speed of chucks

- X/Y-axis positioning accuracy

- X/Y-axis repositioning accuracy

- Weight of single tube

- Dimensions with semi-auto(L*W*H)

Sheet Metal Cutting Machine

Sheet Metal Cutting Machine

Tube Metal Cutting Machine

Tube Metal Cutting Machine

Sheet and Tube Cutting Machine

Sheet and Tube Cutting Machine

Thermoforming and Processing

Thermoforming and Processing

Bending Machine

Bending Machine

Handheld Laser Welding Machine

Handheld Laser Welding Machine

Automation Equipment

Automation Equipment

Profiles Laser Cutting Machine

Profiles Laser Cutting Machine