GB

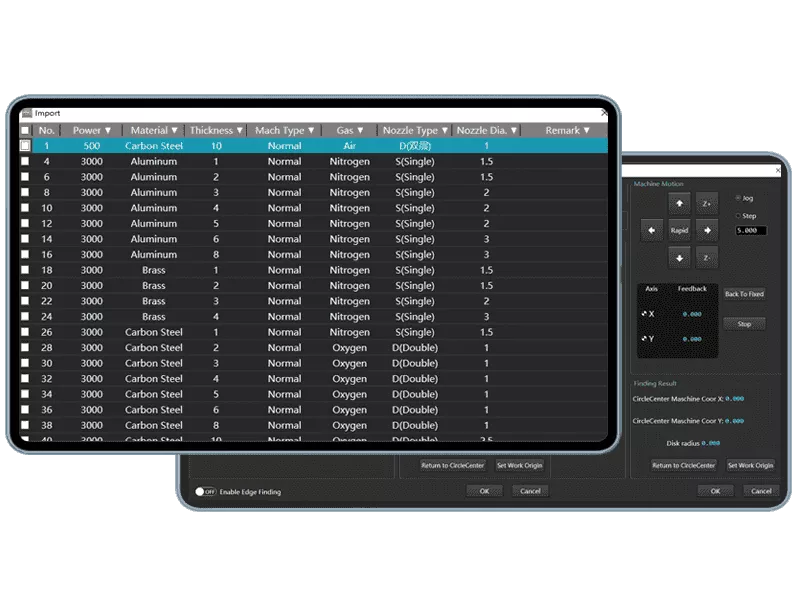

Alpha A Control System

This system is easy to be operated and rich in functions. Even green hands can cut high-quality samples.

Double Fully-automatic Pneumatic Chucks

* One-key clamping and automatic centering

* Pneumatic clamping with no looseness or slip

* Concave support frame can prevent tube from sagging and deformation

* Clamp both round, square tubes and profiles like channel and angle steel

Professional Nesting Software

* Optimize cutting path

to shorten cutting duration

* Smart typesetting algorithm for the increase of material utilization

Massive Production Database

* Users can invoke cutting technology from the database when cutting sheet

of different materials and thickness

* Have multiple thick sheet cutting technologies like air cutting, counterboring

technology, perfect finish cut (PFC), lightening-fast piercing, etc.

Sheet Metal Cutting Machine

Sheet Metal Cutting Machine

Tube Metal Cutting Machine

Tube Metal Cutting Machine

Sheet and Tube Cutting Machine

Sheet and Tube Cutting Machine

Thermoforming and Processing

Thermoforming and Processing

Bending Machine

Bending Machine

Handheld Laser Welding Machine

Handheld Laser Welding Machine

Automation Equipment

Automation Equipment

Profiles Laser Cutting Machine

Profiles Laser Cutting Machine