TX5R

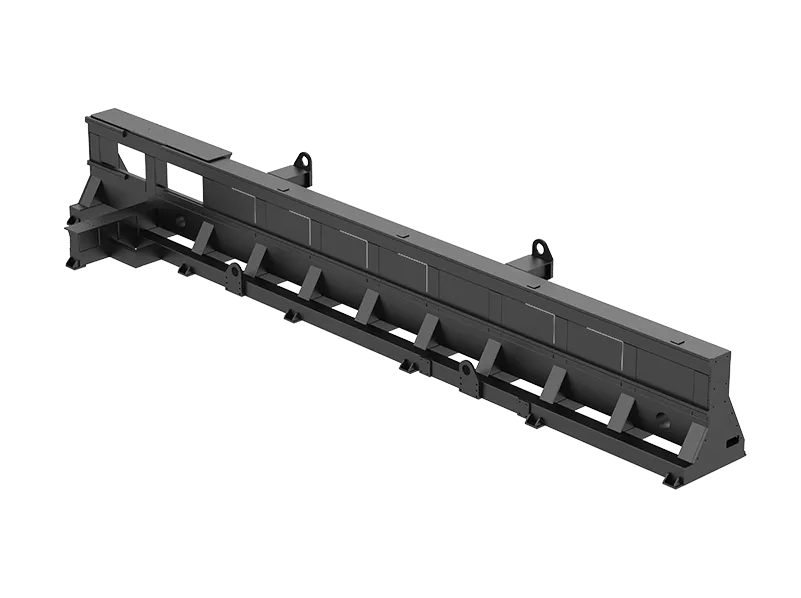

Lateral Hanging Machine Bed

The lateral hanging bed structure reduces the difficulty of manual operation by lowering the height of the center of gravity, improving safety and making it easier for tube loading.

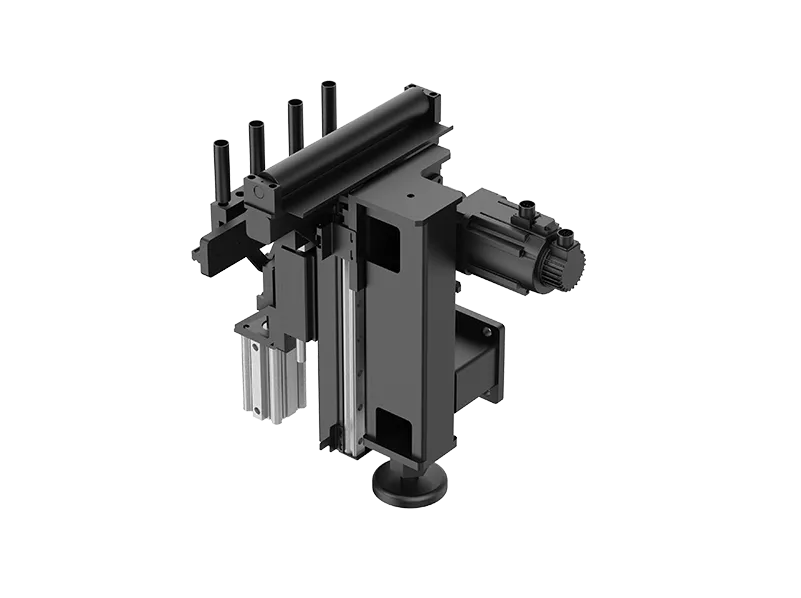

Independent servo follow-up support

Providing sufficient support during the tube cutting process to improve cutting accuracy.

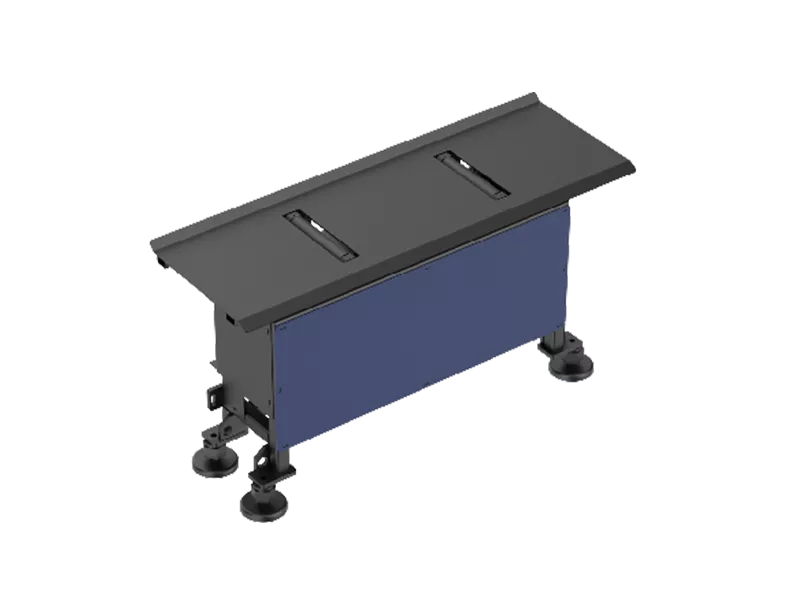

Follow-up Supporting Plate as Unloading Device

Providing support for tube dropping, with high compatibility with tubes, suitable for various sizes, specifications, and types of tubes.

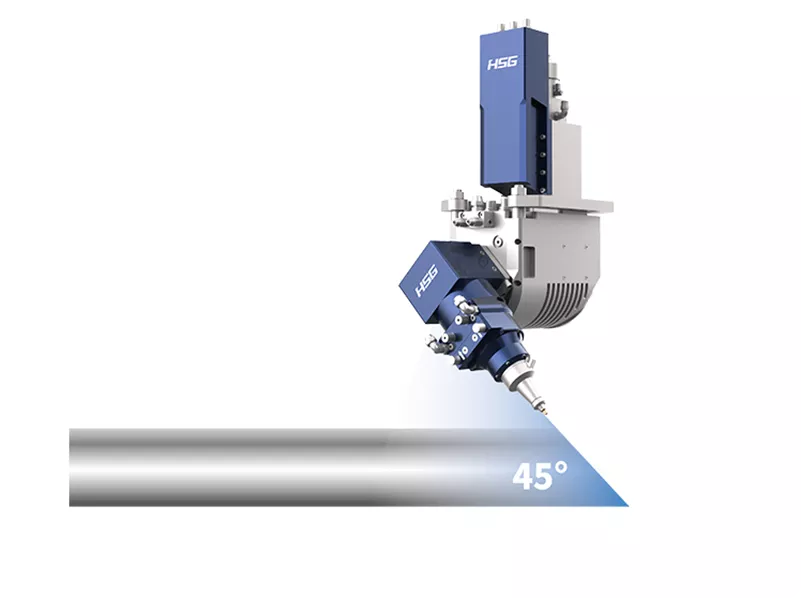

Beveling Processing

Beveling tube cutting head(optional) to achieve 0-45°beveling cutting.

HSG-X10000 Bus System

The system has high integration, covering multiple commonly used operations and rich auxiliary functions for tube processing applications, with simple and convenient operation.

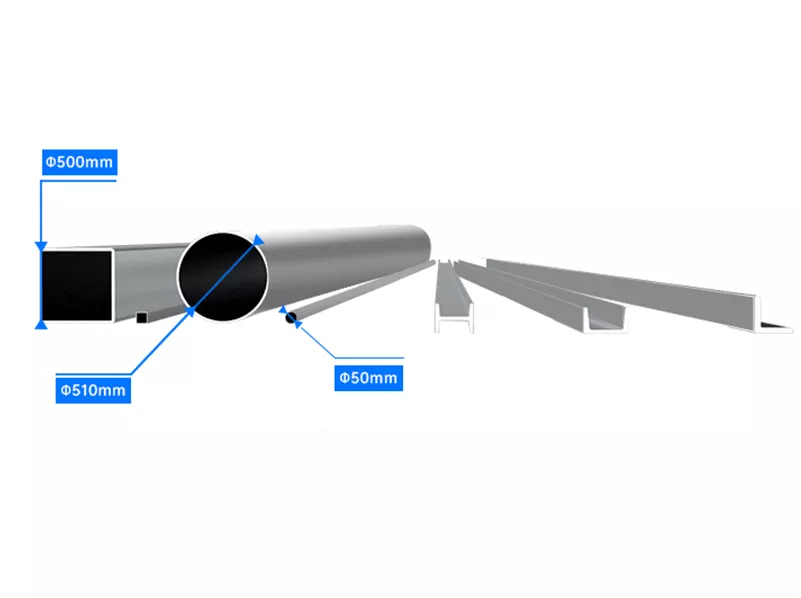

Capable of Processing Heavy Tubes and Profiles

The weight of the single tube is ≤ 2000kg, the diameter range of the round tube is 50-510mm, and the length of the tube can reach 12000mm; It can also support cutting profiles such asangle steel, angle steel, and I-beams.

TX5R

Technical Parameters

- Model

- Power

- Cutting Capacity of Round Tube

- Cutting Capacity of Square Tube

- Chuck Speed

- Max. Linkage Speed

- Acceleration

- Max. Loading Capacity(Single)

- Optional Beveling Cutting

- Control System

Sheet Metal Cutting Machine

Sheet Metal Cutting Machine

Tube Metal Cutting Machine

Tube Metal Cutting Machine

Sheet and Tube Cutting Machine

Sheet and Tube Cutting Machine

Thermoforming and Processing

Thermoforming and Processing

Bending Machine

Bending Machine

Handheld Laser Welding Machine

Handheld Laser Welding Machine

Automation Equipment

Automation Equipment

Profiles Laser Cutting Machine

Profiles Laser Cutting Machine